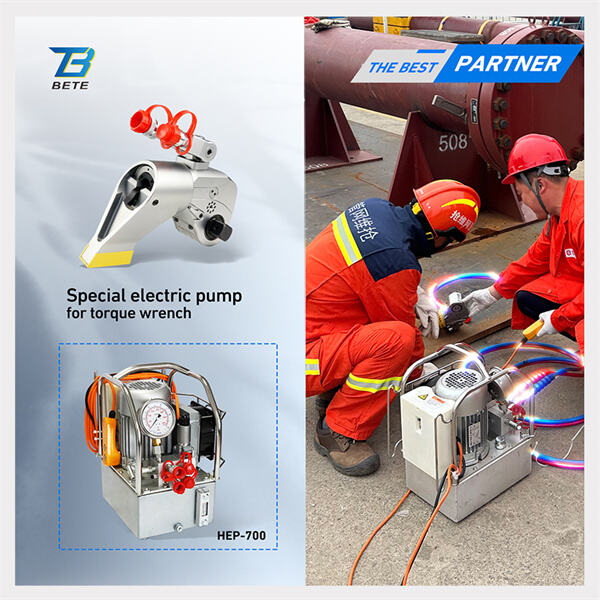

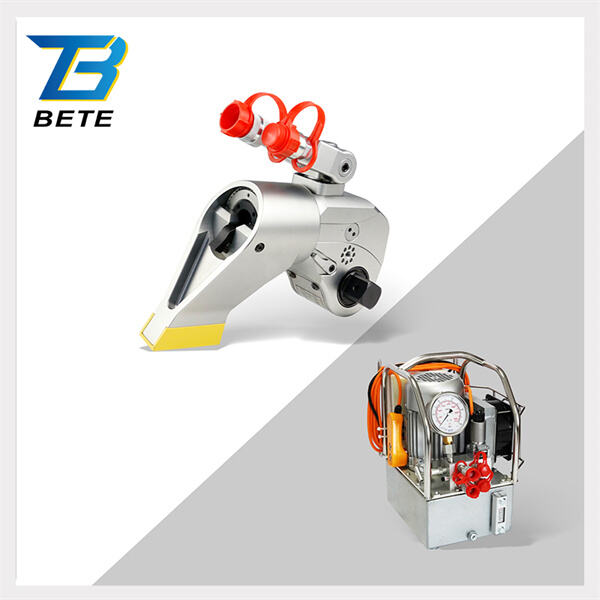

A hydraulic pump is a versatile tool, making the cumbersome work easier and turning them into an efficient piece. They make power that is used to move things by pushing, pulling or blinding them. This is particularly so in industries where heavy machinery are used: This article discusses hydraulic torque wrench pumps and how they can save you time, money, and prevent hand or wrist pain when performing various job tasks.

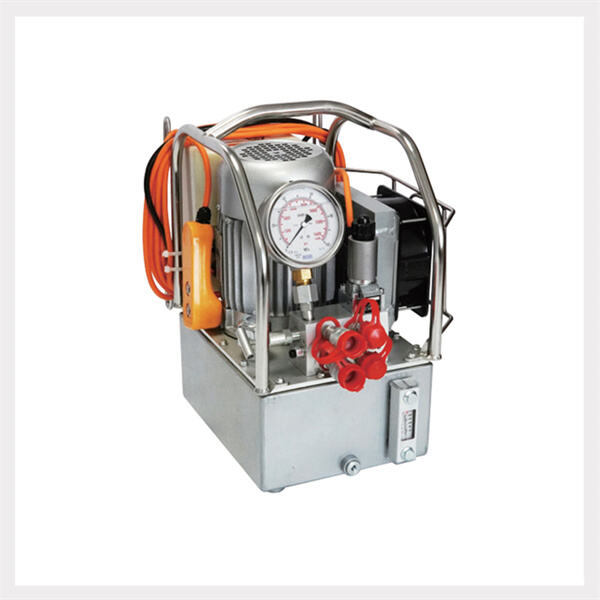

A unique feature of hydraulic pump is that it takes the help from liquid or oil to produce a powerful force. This makes them ideal for heavy-duty applications where high torque is needed such as turning stubborn fasteners (screws or nuts which have been tightened too much), I. E. large bolts, lug nuts on a car and pretty much any bolt/nut that needs breaking loose!) Hydraulic pumps allow workers to easily put pressure on an object, rather than the worker going through arduous work themselves. Without you using your own muscle, and still without a muscular story fueling it exactly. (This lifts with the help of Power Pack hydraulic pump) It only enables them to expend less physical strength meaning they can do more work faster.