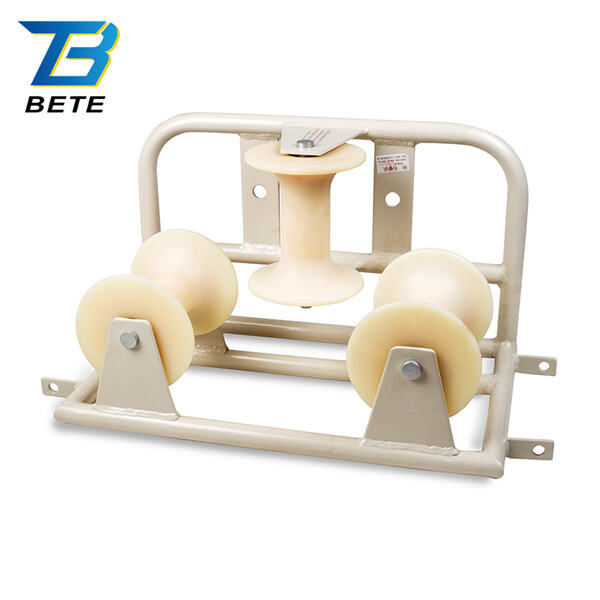

On to some even cooler items of the day, what we are going dive into in more detail today is cable laying tools and equipment! So, just what is cable laying equipment? That is a set of special tools and machines that workers use to insert cables safely and properly. These tools assist to ensure that the cables are mounted correctly, and also, they aid maintain everybody risk-free as you lug out this work. How do these gifted tools work and what can we know about them beyond this?

Decades ago, employees had to perform back-breaking manual labor when laying cables. They were the ones who had to dig trenches with shovels and carry cable by hand. However, with more modern tools and equipment available today than previously ever have been, those that do this job can accomplish their tasks far faster and with a lot less effort. For instance, cable winches are very beneficial since they can be used to move cables through trenches or pipes without requiring laborers exert all of their strength. They can help workers save a lot of muscle and physically 'iron-wrist' work, who are only left with the task to lift cables.