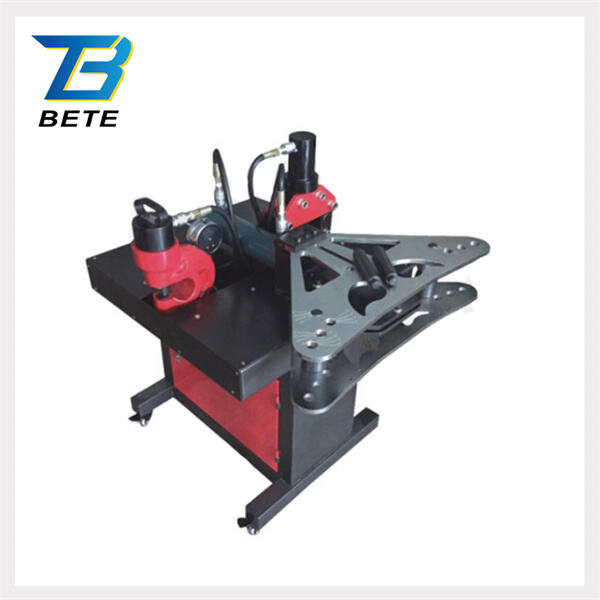

Do you want a great busbar tool to create those nice little entree style spacers. Well, look no further! The Bete busbar punching, bending and cutting machine is a device that meet all requirements. Not only that, but it can also punch holes into material, bend the material and cut shapes so not simplifies your job scheduling as far fewer machines are required for a single product. This allows you to produce busbars much more quickly, which can save an immense amount of time and energy. In short, what can our busbar machine do for your work?

Our Busbar Machine is a versatile machine for anyone, delivering better results quicker. This marvelous machine will assist in making busbars of varying form and measurement without much hassle. As a result, it finds great use in multiple duties such as the construction of electrical panels including switchboards and other critical tools. The busbar machine will keep you capable in order to stay away from and if unavoidable, overwhelm all the backend scare of your tasks so that then one might focus on different parts, right.