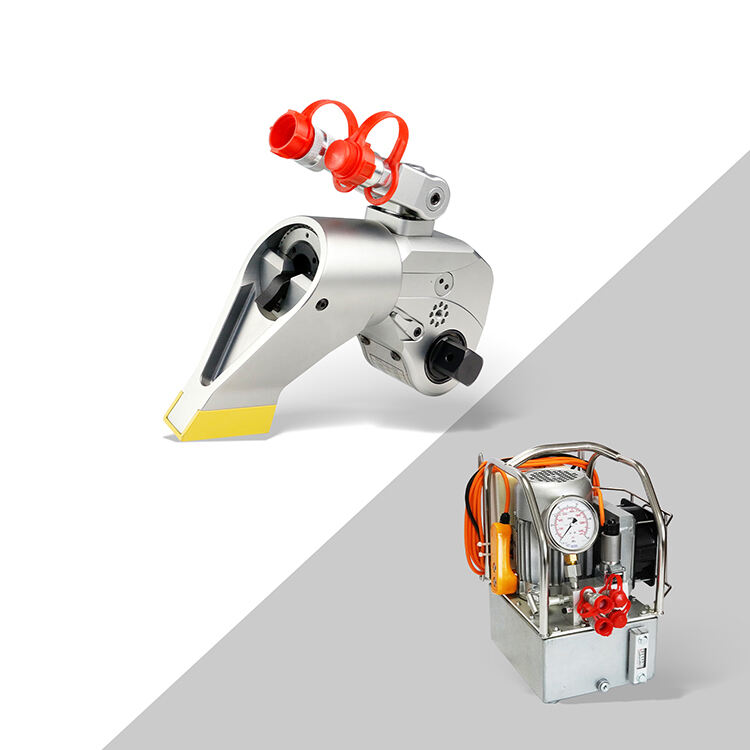

Bu hidrolik torqu vərəni ilə maşınların qaralamağı daha asan və sürətli edir. Bu vərənin necə işlədiyini, nə üçün dəyərli olduğunu və onu tətbiq etməyə görə düşünmədiyiniz bəzi qiymətləndirmələri öyrənmək üçün bu sadə məqaləni oxuyun.

Hidrolik Torqu Vərənini Necə İstifadə Edilir: Adımları Sizə Göstərəcəm

ADIM BİR: İlk adımda, yerine yetecek uygun ölçülü ağırlığı seçmelisiniz. Çalıştığınız makineye uygun olup olmadığını kontrol etmeniz çok önemlidir. Eğer ağırlık doğru şekilde oturmazsa iyi çalışmayacaktır. Bu nedenle herhangi bir şey yapmadan önce rahatlıkla kullanacağınız ağırlığın mükemmel bir şekilde oturacağını kontrol etmelisiniz.

Adım 2: Şimdi, tercih ettiğiniz soketle birlikte makinenize ağırlığı yerleştirin. Bu, ağırlığın makinede tutunduğu şeydir. Çalışırken düşmesini engellemek için güvenle bağlayın. Güvenlik ve verimlilik güvenli bir bağlantısı için çok önemlidir.

Adım 3: Daha sonra ağırlıqda torquyu ayarlamanız lazımdır. Bu, ağırlığın hangi vurucuların veya çivilerin daha sıkı olduğunu anlamasını sağlar. Bu genellikle ağırlığın yüzündeki bir göstərgə (dönen disk) veya ekran ile yapılır. Yapacağınız işin torquy değerini doğru şekilde bilmelisiniz, yanlış ayar sorunlara yol açabilir.

Adım4. Çiviyi və ya yumruğu ayaqlı ilə sıxın.

Adım 5. Sıxmaq üçün ayaqlıdan istifadə edin, bu zaman otorment qiymətinə çatdıqda avtomatik olaraq dayanacaq. Bu xüsusiyyət cihazın zədələnməsini mənfi etmək üçün çox faydalıdır.

Son Adım: Əgər makinada sıxılmalıdır başqa çivilər və ya yumruqlar varsa, eyni prosesi təkrarlayın. Bütün hissələrin düzgün şəkildə bağlanması üçün əmin olmalısınız ki, makinanın yaxşı işləməsi saxlanulsun.

Hidrolik Torque Ayaqlısı Necə İşləyir

Bu ayaqlıdan istifadə edərkən, makinanın texniki tənzimlənməsi daha sürətli və asandır. İşçilərin əllərlə çiviləri və yumruqları sıxması üçün tələb olunan vaxt çox azalır. Hər şeyi əllərlə sıxmaq vaxt alırdı, lakin ayaqlı işçilərin bu işləri çox daha sürətli yerinə yetirməsinə imkan verir.

Ayrıca işçiləri işlərək koruyan bir şəxsiyyətdir. Çox sıxmaq vurğuları və mutqalar maşının pozulmasına səbəb ola bilər, bu da əsasən təsadüfi hadisələrə və yaralanmalarına səbəb olacaqdır. Her şeyin düzgün şəkildə sıxılmasını təmin etmək üçün çiviyə daxil edilmiş mekanizm var, məqsəd isə sizin buna görə məsələlərdən qorunmanızdır. İşlərkən güvənli olmalısınız və bu cihaz da onu təmin edir.

Drij tipi hidrolik torqu vərəni ilə xidməti asanlaşdırın

Drij tipi hidrolik torqu vərəni, vurğuları və mutqaları asan şəkildə sıxmağa kömək edən alət olaraq funksionallaşır. Artıq bunu manual olaraq etmək zəhmətiniz qalmır ki, bu çox işçinin vaxtını götürürdü. hidrolik torqu vərəni pompa onların lazımi torqu-u dəqiq vaxt özündə tətbiq etməyə imkan verir, beləliklə onlar bu diqqəti başqa vacib fəaliyyətlərə yönəltə bilirlər.

Bu ağır məqsədli məc vətərliyin ilk dəfələrdən artıq çox və ya az şəkildə bağlanması qarşısını alır. Bu da, sonra qaytarıb düzəltmək üçün tələb olunan çabaları əgər tamamilə silmirsə də minimum səviyyəyə endirir. Hər şeyi ilk dəfə doğru edərək ümumi texniki idarəetmə prosesi daha da optimallaşdırılır.

Dəst Sistemi Hidrolik Tork Məcləri eyni deyil, lakin onların istifadəsindən universal faydalar var.

Burada bu məclərin maşın idarəetməsi üçün ideal olmasında rolu olan bir neçə şey var:

Onlar çox sıxışdırıcıqlıdır və az təlim tələb edirlər. Nəticədə, hətta yeni gələnlər də öyrənmə eğrisindən asılı olmadan onları işlədə bilirlər. Bu da, proyektə qoşula biləcək yeni işçilər üçün daha asandır.

Onlar çox dəqiqlikdir. Məc, vətərlərin düzgün şəkildə bağlanması ilə əlaqədar olur və bu, maşının idarəedilməsi və avadanlıqdakı hadisələrə qarşı qoruma təmin edilir.

Onlar çox dayanıqlıdır və burada bir çox il qalacaq, Yüksək keyfiyyətli inşaatları ilə bu Hidrolik Torq Şurubu s günü-günə tələbli istifadə şərtləri altında saxlanılmaq üçün hazırlanmışdır. Bu uzun müddət davam edir və keyfiyyətli alətlər almaq istəyən hər hansı bir şirkət üçün maliyetini dəyərləndirir.

Sürət Tipi Hidrolik Torqu Wrenchləri — Pro Nusrətlər.

Bu alətlər sizin üçün hazırlanan bitişləri ilə

Həmişə düzgün ölçülü ağızlıq istifadə edin. Əgər ölçüsü h hidrolik torqu ağızlıq düzgün deyilse, problemlər baş verəcəkdir və bu həm ağızlıq həm də maşın üzərində təsir edə bilər. Başlamaqdan əvvəl həmin ölçüyü yoxlayın.

Bəzi vitkələri ağızlıq adaptoru ilə çatmaq olar Bu xüsusilə vitkələr sıx yerlərdə olduğunda və onları sıxarkən sırtınızı qırmaq istəmirsinizdə faydalıdır.

Hər istifadədən sonra ağızlıq toxunuşunuzu temizləməlisiniz. Bu sadə addımı izləyərək pillinizin daha uzun ömürlü olması və lazımi kimi işləməsi təmin ediləcəkdir. Həftədə bir dəfə toxununuzu temizləmək hər şeyin formada qalmasını təmin edir.

Torq göstəricisini dəqiq yoxlama və ayarlamağın əhəmiyyəti var. Onlar nihayətən istifadə ilə bitir, bu səbəbdən onların yaxşı haldə olmalarını saxlamaq vacibdir. Planlaşdırılmış yoxlamalar ömrü uzadır.

Mündəricat

- Hidrolik Torqu Vərənini Necə İstifadə Edilir: Adımları Sizə Göstərəcəm

- Hidrolik Torque Ayaqlısı Necə İşləyir

- Drij tipi hidrolik torqu vərəni ilə xidməti asanlaşdırın

- Burada bu məclərin maşın idarəetməsi üçün ideal olmasında rolu olan bir neçə şey var:

- Sürət Tipi Hidrolik Torqu Wrenchləri — Pro Nusrətlər.